Flow Sensors

Precise flow control is the basis for safe and efficient processes in almost all applications. But when is a flow meter, a flow switch, the electro-magnetic, turbine, Coriolis/density, ultrasonic or calorimetric technology better? Find the best solution for your application...

FLOW-HOW made by Anderson-Negele

When 40+ years of Mag Flow Expertise meet 90+ years of Hygienic Sensor Competence:

After the integration of the GEA Diessel magnetic flow meter business, its sensor range, and specialized staff, Anderson-Negele have become your hygienic instrumentation specialists with the “FLOW-HOW”.

How can flow sensors and flow switches optimize processes, ensure product quality, and save costs?

How can a flow sensor save costs?

How can a flow switch save costs?

What are the possible measuring methods for flow measurement?

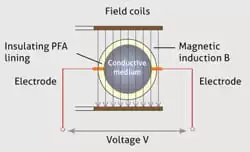

What is the magnetic-inductive flow measurement?

Which products are suitable for magnetic-inductive flow measurement?

Starting from a minimum conductivity of > 5 μS/cm, the induced voltage can be measured. This technique is suitable for media such as milk, cream, beer, ketchup, sauces, creams, mash, molasses, yogurt, concentrates, cleaning media, and many others.

What is turbine flow measurement?

Which products are suitable for turbine flow measurement?

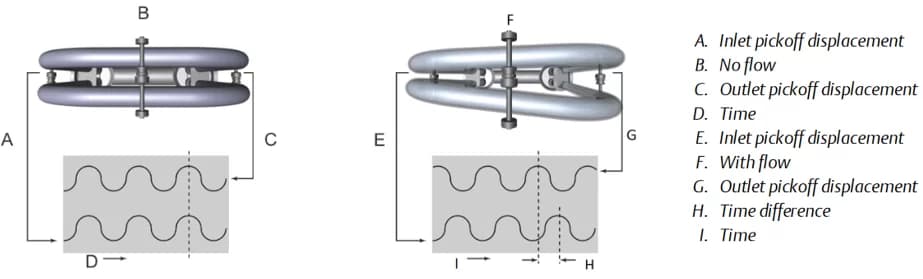

What is Coriolis mass flow measurement?

Which products are suitable for Coriolis flow meters?

These measuring instruments are suitable for almost all production processes in the food and beverage industry and are particularly advantageous in applications where the density (or concentration, Brix, Plato, Proof or Baumé value) must be determined at the same time as the flow rate.

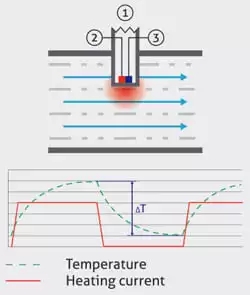

What is a calorimetric flow switch?

Which products are suitable for a calorimetric flow switch?

This measuring principle is ideal for all aqueous products, including demineralized and highly filtered media such as cola and other soft drinks, filtered beer, demineralized water, as well as for media in pressure lines.

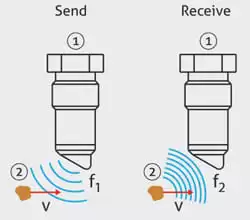

What is an ultrasonic flow switch?

Which products are suitable for an ultrasonic flow switch?

Which products are suitable for an ultrasonic flow switch?

What is the Flex-Hybrid technology with IO-Link and 4…20mA parallel?

HYGIENIC BY DESIGN™: What does hygienic design mean for flow sensors?